| TECHNICAL DATA | HTZ 1000 |

|---|---|

| Productivity: | up to 27 m3/8h* |

| Max. log diameter: | 900 mm |

| Max. cutting width: | 850 mm |

| Max. log length: | custom made |

| Diameter of flywheels: | 1020 mm |

| Width of flywheels: | 105 mm |

| Blade length: | 6200 mm |

| Blade width: | 120** mm |

| Blade thickness: | 1,1 mm |

| Approximate weight: | 3800 - 5000 kg*** |

| Width: | 2600 mm |

| Total height (blade in highest position): | 2600 mm |

| Total length: | log length + 3,5m |

| Main motor power: | 11/15/18,5/22/30 kW |

** blades for two sided cutting are 20 mm wider

*** depends on machine’s configuration

Mebor’s affordable HTZ 1000 makes it possible for small sawmills to cut with professional precision and speed. The machine includes heavy cast steel wheels with wide blades, full hydraulics for log manoeuvring and Mebor System® automatic control.

Key features:

- strong and durable, low maintenance costs,

- heavy duty log turners,

- simple and automated, one man operation,

- available in a fully hydraulic or simple mechanical version.

Equipment

Band Saw Head Equipment

Blade lubrication/ cooling systems.

Laser, showing the cutting height.

Saw dust extraction container/ box etc.

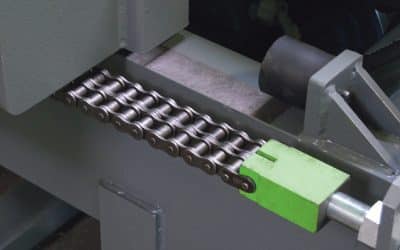

High speed chain

driven band saw head feeding; fast return speed.

Angled saw head

- blade enters into the wood faster.

Manually controlled pre-cutter;

extends blade life; follows log shape automatically.

Hydraulicaly moveable saw blade guide.

manual hydraulic tensioning

of the blade, maintains the correct pressure.

Heavy cast steel wheels

for high precision and sawing performance. Option: variable speed.

Band Saw Bed - Log Manoeuvring Equipment

Log loading device

Longitudinal rollers

Vertical arms

Left-right movement of the log turning devices.

Log turner with an adoptable chain

and gearbox for more power.

Hydraulic clamps

with optional adjustable height.

Board Removal Equipment

Automatic board guiding

device - maintains straight direction of boards during removal.

Standard board pusher

(opt. lifting function).

Belt conveyor

for auto. board removal.

Platform with a roller

for collecting of boards

Control

Optical, CE certified, safety fence for hands free operation

MEBOR SYSTEM automatic control V130

Fully automated sawing. Opt. hands free control. Fast choice of sizes. Choice of sizes in advance.

MEBOR SYSTEM single automatic control M91

Band Saws Compare Table

| Max.Log diameter (mm) | Productivity (m3/8h) * | Blade width (mm) ** | Main motor power (kW) | Approximate weight (kg) *** | Product |

|---|---|---|---|---|---|

| 900 | up to 25 | 100 | 11/15/18,5/22 | 2900 - 3800 | HTZ 800 |

| 900 | up to 25 | 100 | 11/15/18,5/22 | 2900 - 3800 | HTZ 800 Mobile |

| 900 | up to 27 | 120 | 11/15/18,5/22/30 | 3800 - 5000 | HTZ 1000 |

| 900 | up to 27 | 120 | 11/15/18,5/22/30 | 3800 - 5000 | HTZ 1000 Mobile |

| 1000 | up to 38 | 120 | 18,5/22/30/37 | 5500 - 7500 | HTZ 1100 PRO |

| 1000 | up to 38 | 120 | 18,5/22/30/37 | 5500 - 7500 | HTZ 1100 Mobile |

| 1200 | up to 35 | 140 | 30/37/45/55 | 5500 - 7000 | HTZ 1200 Professional |

| 1200 | up to 35 | 140 | 30/37/45/55 | 6000 - 7500 | HTZ 1200 SP |

| 1200 | up to 60 | 160 | 37/45/55 | 11000 - 14000 | HTZ 1200 PLUS |

| 1250 | up to 48/80 | 180 | 55/75 | 14000 - 17000 | HTZ 1300 PLUS |

| 1600 | up to 50 | 160 | 37/45/55 | 15000 - 18000 | HTZ 1200 SP EXTREME 15 |

| 1800 | up to 50 | 160 | 37/45/55/75 | 20000 - 24000 | HTZ 1200 SP EXTREME 18 |

| 2000 | up to 65/90 | 206 | 90/110 | 25000 - 32000 | HTZ 1400 SP EXTREME 20 |

* depends on log sizes, sawn wood dimensions, machine’s configuration etc

** blades for two sided cutting are 20 mm wider

*** depends on machine's configuration

About Mebor Band Saws

Mebor System® is our own system of horizontal band saws, which sets us apart from our competitors. With a Mebor band saw you will increase your productivity and yield, as well as decrease labour costs.

Wood is unpredictable and for this reason Mebor band saws have a strong and robust construction. It guarantees reliability of functioning and minimises maintenance costs.

Band saws adapted for your needs – for small and big sawmills. Every Mebor band saw is custom made; therefore we supply each customer an optimal band saw for his needs. We will advise which model is most suitable for your needs and requirements. We will also adjust the configuration of the band saw; for example the distances between clamps according to the lengths of logs, equipment etc.

Automatic board removing (Mebor System® )

We were the first to introduce the board removing system, which saves your time. After the band saw cuts a board, the board pusher pushes it off the band saw bed during the return of the band saw head. Simple and automatic, with no manual work.

Automatic functioning - Mebor System® Labour costs present a big share of costs in sawmills. Regardless of whether it is a small model, or a bigger and faster Mebor band saw model, all of them include automatic guidance. If necessary, this allows the operator to also stack boards on his own, simultaneously during sawing! As it is a one man operation, the labour costs are minimised. The operator should focus on the productivity, quality of wood and output, not on the machine operation. This is done instead of you by the Mebor band saw and you can increase the profit of your company. The control is simple and user friendly. Our customers learn how to operate the machine in a few hours.

Mebor System® leads the operator during cutting. It provides important information, which helps him choose the optimal cutting for best output. Manual control is also available for less demanding users.

Full log manoeuvring equipment is available for fast and effortless work.

Quick and low cost installation Mebor band saws are installed in one day and do not require any special foundations. Precision of cutting is ensured by the solid construction and wide blades. All Mebor band saws are using wide blades (80-210 mm wide). The fact is that wide blades provide higher sawing speed, as well as better sawing precision. The high quality of your products will increase the satisfaction of your customers.

Contact MEBOR